A Comprehensive Guide to organic peroxides series applications

The Organic Peroxides Series represents a critical class of chemical compounds that serve as powerful initiators and crosslinking agents across a vast spectrum of industrial processes. Characterized by the weak oxygen-oxygen single bond in their structure, these compounds readily decompose to generate free radicals. These radicals are highly reactive species that can initiate chain reactions, most notably the polymerization of monomers into plastics and rubbers. The versatility of the Organic Peroxides Series stems from the wide variety of available molecules, each engineered to decompose at specific temperatures and rates, allowing for precise control over industrial processes. From the production of ubiquitous plastics like PVC and polystyrene to the curing of high-performance composites used in aerospace, the applications are both foundational and advanced. Understanding these applications is key to appreciating how modern materials are manufactured and tailored for specific performance characteristics, impacting everything from the car you drive to the pipes in your home.

Polymer Industry: The Backbone of Modern Plastics

In the polymer industry, organic peroxides are indispensable. They are primarily used as initiators in the polymerization of various monomers.

- Polyethylene (PE) Production: Low-density polyethylene (LDPE) is manufactured using high-pressure free-radical polymerization, where organic peroxides are the key initiators.

- Polyvinyl Chloride (PVC) Polymerization: Peroxides are used to initiate the suspension or emulsion polymerization of vinyl chloride monomer.

- Polystyrene (PS) and Acrylates: They are crucial for initiating the polymerization of styrene and various acrylate monomers to produce a wide range of plastics and coatings.

Crosslinking Elastomers: From Tires to Hoses

Crosslinking, or vulcanization, is a process that transforms individual polymer chains into a three-dimensional network, dramatically improving the material's mechanical properties, thermal stability, and chemical resistance.

- Tire Manufacturing: While sulfur vulcanization is common for natural rubber, organic peroxides are used for crosslinking specific synthetic rubbers like EPDM, providing excellent heat and ozone resistance.

- Wire and Cable Insulation: Crosslinking polyethylene (XLPE) with peroxides enhances its temperature resistance and mechanical strength, making it ideal for insulating high-voltage cables.

- Automotive Hoses and Belts: Peroxide-cured elastomers offer superior durability and resistance to oils and heat, essential for demanding automotive applications.

Composite Materials and Curing

In the composites industry, organic peroxides are used to cure thermosetting resins, binding reinforcing fibers like glass or carbon together to create strong, lightweight materials.

- Fiberglass-Reinforced Plastics (FRP): Peroxides are used to initiate the curing of polyester and vinyl ester resins in the production of boat hulls, storage tanks, and automotive parts.

- Sandwich Panel Core Materials: They are used to cure the resin in structural honeycomb or foam core materials used in aerospace and construction.

Other Niche Industrial Uses

The unique reactivity of the Organic Peroxides Series lends itself to other specialized applications.

- Textile Industry: Used for the degradation and modification of natural fibers like cellulose to improve their properties.

- Electronics: Employed in the etching and cleaning of circuit boards.

- Chemical Synthesis: Serve as oxidizing agents or intermediates in the synthesis of various organic chemicals and pharmaceuticals.

Spotlight on a Key Player: dicumyl peroxide crosslinking agent

Within the vast Organic Peroxides Series, dicumyl peroxide stands out as one of the most widely used and effective crosslinking agents. It is an organic compound with a high decomposition temperature, making it particularly suitable for processing polymers that require elevated temperatures. Its primary role is to create covalent bonds between polymer chains, a process known as crosslinking, which fundamentally alters the material's properties. When heated, dicumyl peroxide decomposes to form two cumyloxy radicals. These radicals then abstract hydrogen atoms from the polymer backbone, creating polymer radicals that subsequently combine to form stable carbon-carbon crosslinks. This mechanism is highly efficient and results in a thermally stable network. The choice of dicumyl peroxide crosslinking agent is often driven by its cost-effectiveness, high efficiency, and the excellent heat and aging resistance it imparts to the final product, making it a staple in the plastics and rubber industries.

What Makes Dicumyl Peroxide Special?

Several properties make dicumyl peroxide a preferred choice for many crosslinking applications.

- High Decomposition Temperature: It has a relatively high half-life temperature, allowing it to be used in high-temperature processing without premature decomposition.

- Efficiency: It is a very efficient crosslinking agent, requiring relatively low concentrations to achieve a high degree of crosslinking.

- Stability: It is relatively stable during storage and handling when kept at recommended temperatures.

- Byproducts: Its decomposition byproducts (acetophenone and cumyl alcohol) are relatively non-volatile and non-discoloring, which is important for applications where appearance matters.

Mechanism of Action: How it Crosslinks Polymers

The crosslinking process is a free-radical chain reaction. Upon heating, the weak O-O bond in dicumyl peroxide homolytically cleaves to form two cumyloxy radicals. These radicals are highly reactive and seek to stabilize themselves by abstracting a hydrogen atom from a polymer chain (R-H), creating a polymer radical (R•) and a molecule of cumyl alcohol. Two polymer radicals then combine to form a covalent crosslink (R-R), linking the two polymer chains together permanently.

Ideal Polymers for Dicumyl Peroxide Use

Dicumyl peroxide is particularly effective for crosslinking saturated and unsaturated polymers.

- Polyethylene (PE): Used to produce crosslinked polyethylene (XLPE) for wire insulation and piping.

- Ethylene Propylene Diene Monomer (EPDM): A key agent for vulcanizing EPDM rubber for automotive seals and hoses.

- Silicone Rubbers: Used in the curing of certain silicone elastomers.

- Polypropylene (PP): Can be used to modify the properties of polypropylene through controlled degradation or crosslinking.

Advantages and Limitations

While highly effective, it's important to consider both the pros and cons of using dicumyl peroxide.

| Advantages | Limitations |

| Provides excellent heat and chemical resistance. | Requires high processing temperatures, which may not be suitable for all polymers. |

| Creates non-reversible carbon-carbon crosslinks. | Can cause some polymer degradation (chain scission) if not carefully controlled. |

| Relatively low odor and low volatility of byproducts. | Slower decomposition rate compared to some other peroxides, which can affect cycle times. |

| Cost-effective for large-scale industrial applications. | Not suitable for applications requiring low-temperature curing. |

Prioritizing Safety: Understanding the organic peroxide safety data sheet

Handling any member of the Organic Peroxides Series demands the utmost respect and a rigorous commitment to safety. These compounds are, by their very nature, thermally unstable and can be hazardous if mishandled. The single most important document for ensuring safe use is the organic peroxide safety data sheet (SDS), formerly known as a Material Safety Data Sheet (MSDS). This document, mandated by regulatory bodies like OSHA and REACH, provides a comprehensive overview of the substance's properties, hazards, and necessary precautions. It is not merely a technical sheet but a critical tool for risk assessment, emergency planning, and employee training. Understanding how to read and interpret the SDS is a non-negotiable skill for anyone involved in the manufacturing, handling, storage, or disposal of organic peroxides. It details everything from the required personal protective equipment (PPE) to specific first-aid measures and firefighting procedures, forming the bedrock of a robust safety culture in any facility where these powerful chemicals are present.

Decoding Section 1: Identification and Hazards

Section 1 of the SDS provides the essential identifiers: the product name, synonyms, recommended uses, and the supplier's contact information. It also includes emergency contact information. Section 2, Hazard(s) Identification, is arguably the most critical for initial risk assessment. It details the GHS (Globally Harmonized System) classification, including signal words (e.g., "Danger"), hazard statements (e.g., "May be fatal if swallowed," "Heating may cause a fire"), and pictograms (e.g., flame over circle, exploding bomb). This section provides an immediate understanding of the primary dangers.

Key Handling and Storage Precautions

Section 7 of the SDS outlines the safe handling and storage practices. This information is vital for preventing accidents.

- Handling: Advises on engineering controls (like ventilation), PPE (gloves, safety glasses, flame-resistant clothing), and hygiene practices (e.g., no eating or drinking in work areas).

- Storage: Specifies temperature requirements (e.g., "Keep refrigerated"), the need for temperature control devices, and segregation from incompatible materials like accelerators, reducing agents, and flammable materials.

First-Aid Measures and Fire-Fighting Procedures

Sections 4 and 5 provide life-saving information in case of exposure or fire.

- First-Aid (Section 4): Gives clear instructions for inhalation, skin contact, eye contact, and ingestion. It emphasizes the need for immediate medical attention in many cases.

- Fire-Fighting (Section 5): Lists suitable extinguishing media (e.g., water spray, dry chemical, CO2) and unsuitable media (e.g., direct water jet on a fire). It also highlights specific hazards from combustion, such as toxic fumes.

Toxicological and Ecological Information

Sections 11 and 12 provide information on health and environmental impacts.

- Toxicological Information (Section 11): Details routes of exposure, symptoms of exposure, and any known chronic effects.

- Ecological Information (Section 12): Provides data on toxicity to aquatic life, persistence, and degradability, which is crucial for environmental risk assessment and disposal planning.

The Chemistry of Creation: peroxide initiator for polymerization

The creation of the world's most common plastics is impossible without a catalyst to start the reaction, and this is where the peroxide initiator for polymerization plays its starring role. Polymerization is the process of chemically bonding monomer molecules together to form long-chain polymers. Most common plastics are made via free-radical polymerization, a chain reaction that needs a trigger to begin. Organic peroxides are perfectly suited for this role due to their weak O-O bond, which breaks easily upon heating to generate free radicals. These radicals attack the double bond of a monomer (like ethylene or styrene), creating a new, larger radical. This radical then attacks another monomer, propagating the chain reaction at an explosive rate. The choice of peroxide initiator is a critical decision in polymer manufacturing, as it directly controls the reaction rate, the molecular weight of the polymer, and the temperature at which the process can be run. By selecting a peroxide with the appropriate decomposition temperature and half-life, engineers can fine-tune the process for maximum efficiency and product quality.

The Role of an Initiator in Chain Reactions

A peroxide initiator is the starting gun of a polymerization chain reaction. Without it, monomers can coexist at high temperatures without reacting. The initiator's sole purpose is to provide the initial free radicals that kickstart the process. Once the reaction is initiated, it becomes self-propagating until the monomers are exhausted or the radicals are terminated.

Free Radical Polymerization Explained

The process occurs in three main steps:

- Initiation: The peroxide decomposes to form free radicals.

- Propagation: The radicals attack monomer molecules, adding them to the chain and creating new radicals at the chain end, which continue the process.

- Termination: Two growing radical chains combine, or a radical chain abstracts a hydrogen atom, ending the growth of that polymer chain.

Choosing the Right Peroxide Initiator for Your Monomer

The selection depends on several factors related to the monomer and the desired process conditions.

- Monomer Reactivity: Some monomers polymerize more easily than others and may require a less reactive initiator.

- Process Temperature: The initiator's decomposition temperature must match the temperature of the polymerization reactor.

- Desired Polymer Properties: The rate of initiation affects the molecular weight distribution, which in turn influences the final polymer's properties like strength and melt viscosity.

Controlling Reaction Rate and Temperature

The organic peroxide decomposition temperature is the key lever for controlling the reaction. Peroxides are characterized by their half-life temperature (the temperature at which half of the peroxide decomposes in one hour). By choosing a peroxide with a specific half-life at the desired reaction temperature, manufacturers can control the rate of radical generation and thus the overall polymerization rate, ensuring a safe and efficient process.

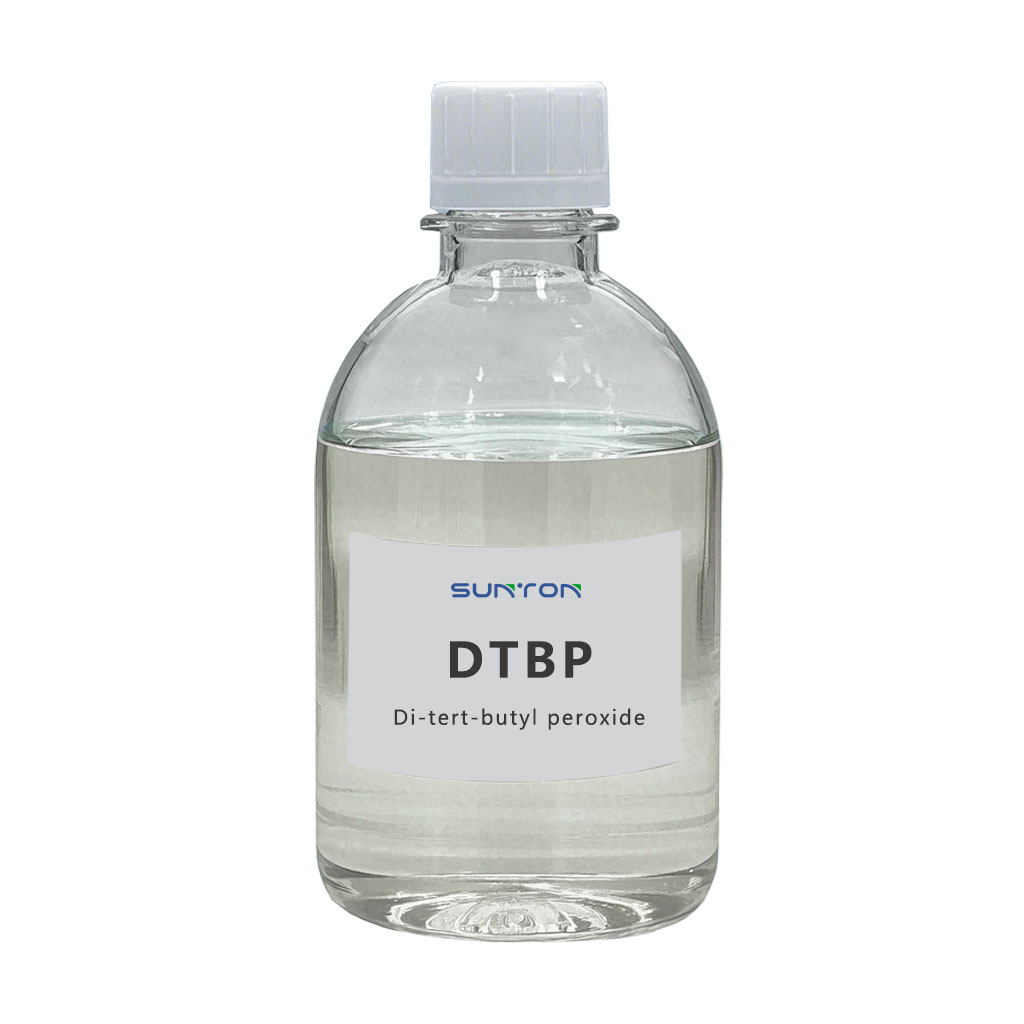

A Critical Parameter: organic peroxide decomposition temperature

Perhaps the single most important physical property governing the use of any compound in the Organic Peroxides Series is its organic peroxide decomposition temperature. This is not a single, fixed point but rather a range that describes the thermal stability of the molecule. The weak peroxide bond (-O-O-) is thermally labile, meaning it breaks down when heated, releasing energy and forming free radicals. This property is both the reason for its utility as an initiator and the source of its primary hazard. Understanding and managing this decomposition temperature is central to the safe handling, storage, and application of organic peroxides. If a peroxide is exposed to temperatures above its decomposition point, it can lead to a runaway reaction, resulting in fire or explosion. Therefore, every process design, storage facility, and transportation protocol is built around this critical parameter. Selecting the right peroxide involves matching its decomposition profile to the thermal requirements of the application, ensuring that it is stable enough to be handled safely but reactive enough to perform its function efficiently at the desired processing temperature.

Defining Half-Life Temperature (T1/2)

The decomposition rate is not linear and is best described by its half-life. The half-life temperature ($T_{1/2}$) is the temperature at which 50% of the peroxide decomposes in a specific time, typically one hour. For example, a peroxide with a $T_{1/2}$ of 10 hours at 100°C is more stable than one with a $T_{1/2}$ of 1 hour at 100°C. Manufacturers provide $T_{1/2}$ data at various temperatures, allowing users to accurately predict the peroxide's behavior under their specific process conditions.

Factors Influencing Decomposition Temperature

The chemical structure of the peroxide itself is the primary determinant of its decomposition temperature.

- Substituents: Electron-withdrawing groups near the peroxide bond can destabilize it, lowering the decomposition temperature. Bulky groups can provide steric hindrance, sometimes increasing stability.

- Dilution: Peroxides are often sold diluted in a solvent or on an inert carrier (like phthalates or water). This dilution significantly increases their thermal stability and makes them safer to handle.

- Contamination: Contact with certain materials, especially metal ions or accelerators, can catalyze decomposition and lower the effective decomposition temperature.

Practical Implications for Processing and Safety

The decomposition temperature dictates every aspect of handling and use.

- Storage: Peroxides must be stored well below their decomposition temperature, often with refrigeration for more sensitive types. Temperature monitoring is mandatory.

- Processing: The processing temperature must be carefully controlled to ensure the peroxide decomposes at the desired rate. Too slow, and the reaction is incomplete; too fast, and it can lead to a runaway.

- Safety: All equipment must be designed to avoid hot spots. Emergency cooling systems must be in place to prevent temperatures from exceeding critical levels.

How to Select a Peroxide Based on its Temperature Profile

The selection is a balancing act between safety and performance.

| Application Type | Required Temperature Profile | Example Peroxide Type |

| Low-Temperature Curing (e.g., some resins) | Low decomposition temperature (active at 50-100°C). | Peroxyesters (e.g., t-butyl peroxybenzoate). |

| Polymerization (e.g., LDPE) | Medium decomposition temperature (active at 150-250°C). | Peroxyketals (e.g., t-butyl peroxy-2-ethylhexyl carbonate). |

| Crosslinking (e.g., XLPE) | High decomposition temperature (active above 200°C). | Dialkyl peroxides (e.g., dicumyl peroxide). |

FAQ: Your Top Questions About Organic Peroxides Answered

Are organic peroxides dangerous?

Yes, organic peroxides can be dangerous if not handled correctly. Their primary hazard is their thermal instability; they can decompose exothermically, releasing heat and flammable gases. This can lead to a self-accelerating decomposition, which can result in a fire or explosion. The level of hazard varies greatly depending on the specific peroxide, its concentration, and its form (pure vs. diluted). This is why strict adherence to the organic peroxide safety data sheet, proper storage temperature control, and segregation from incompatible materials are non-negotiable safety practices.

How should organic peroxides be stored?

Safe storage is paramount and is dictated by the organic peroxide decomposition temperature. Key principles include: storing in a cool, dry, well-ventilated area away from direct sunlight and heat sources; maintaining storage temperatures significantly below the peroxide's self-accelerating decomposition temperature (SADT); using temperature monitoring and alarm systems; storing in their original, properly labeled containers; and segregating them from all incompatible materials, especially accelerators, strong acids, bases, flammable solvents, and reducing agents. The organic peroxide safety data sheet will provide the specific temperature requirements and incompatibilities for each product.

What is the difference between a crosslinking agent and an initiator?

While both are functions performed by the Organic Peroxides Series, they describe different roles in a chemical process. An initiator is used to start a polymerization reaction, creating long polymer chains from monomers. A crosslinking agent is used to link existing polymer chains together to form a network, which changes a thermoplastic into a thermoset or enhances the properties of an elastomer. Some peroxides can be used for both purposes, but the choice depends on the desired outcome. For example, in making XLPE, the peroxide acts as a crosslinking agent, while in making LDPE, it acts as a peroxide initiator for polymerization.

Can organic peroxides be used in food-grade applications?

Generally, no. Organic peroxides are reactive chemical substances and are not intended for direct food contact. However, they play an indirect but crucial role in the food packaging industry. They are used as initiators and crosslinking agents in the manufacturing of the polymers that are used to create food packaging materials, such as certain plastics and coatings. The key is that the peroxide and its decomposition byproducts must be fully consumed or removed during the manufacturing process, ensuring the final packaging material meets strict regulatory standards for food safety and does not migrate harmful substances into the food.

English

English 中文简体

中文简体

By Admin

By Admin