Caprylohydroxamic Acid (CHA), chemically known as Octanohydroxamic Acid (C8H17NO2), is a medium-chai...

READ MORE-

Organic Synthesis Field

-

Agriculture Field

-

Fuels And Coatings Industry

-

Transportation

-

Electronic Andelectrical Equipment

-

Textile Fabrics

-

Hair Care Products

-

Makeup Products

-

Skin Care Products

-

Quality

-

Customization

-

Cost

-

Capacity

-

Service

-

We have our own testing lab and the advanced and complete inspection equipment, which can ensure the quality of the products.

-

We have a strong R&D team, we can customize and produce products according to the customers' requirements.

-

We own three factories of our own. So we can provide preferential prices and good products directly.

-

Our annual production capacity is over 20000 tons, we can meet the needs of different customers with different purchase quantities.

-

We focus on developing high-quality products for top-end markets. Our products are in line with international standards, and are mainly exported to European, American, and Asian countries.

-

0+

Annual Output

-

0+

Global Cooperative Customers

-

0+

Technical Staff

-

0+m²

Advanced Factory

-

-

The global demand for high-purity humectants is reaching new heights as consumers demand safer perso...

READ MORE -

What is 1,2-Hexanediol in Modern Cosmetics? 1,2-Hexanediol is a multifunctional glycol used primaril...

READ MORE -

What is Benzoyl Peroxide (BPO) in Chemical Manufacturing? Benzoyl Peroxide (BPO) is a white, crystal...

READ MORE -

As global demand for specialty chemicals continues to grow, Acethydrazide has become an increasingly...

READ MORE

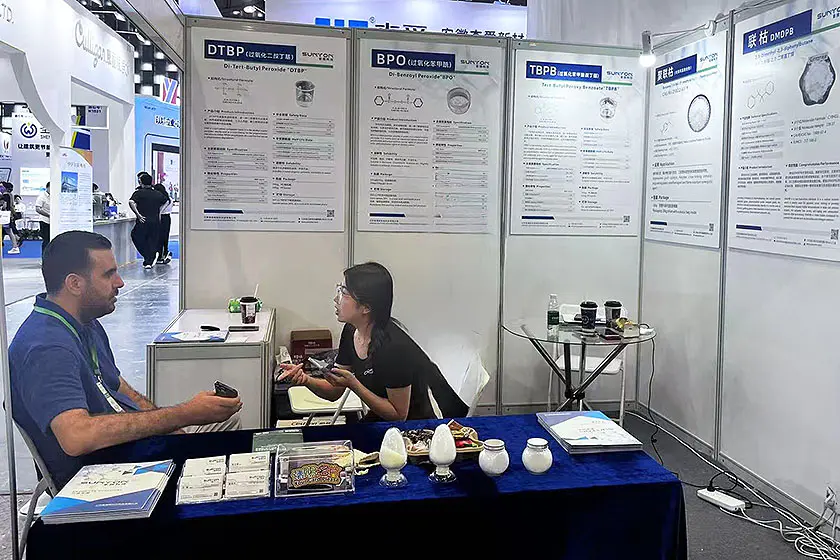

Key Industrial Peroxides: Properties and Applications of TBPB, BPO, and DTBP

Peroxides are a class of organic compounds containing an oxygen-oxygen single bond (–O–O–). Among them, three significant members are Tert-Butyl Peroxybenzoate (TBPB), Benzoyl Peroxide (BPO), and Di-Tert-Butyl Peroxide (DTBP). These compounds are widely utilized in various industrial and chemical processes due to their unique properties, particularly their ability to decompose and generate free radicals, which facilitate polymerization, oxidation, and other chemical reactions.

Tert-Butyl Peroxybenzoate (TBPB)

Applications:

Polymerization Initiator: TBPB is commonly used as a polymerization initiator, particularly in the production of polyvinyl chloride (PVC) and other polymers. It decomposes at elevated temperatures to form free radicals, initiating the polymerization process.

Cross-Linking Agent: In the production of cross-linked polymers and resins, TBPB helps improve the mechanical properties and thermal stability of the final product.

Curing Agent: It is also employed as a curing agent in the manufacturing of certain types of rubbers and plastics, enhancing their durability and performance.

Safety and Handling:

TBPB is a reactive compound that must be handled with care. It is a powerful oxidizer and can pose fire and explosion hazards if not stored and used correctly. Appropriate safety measures, including the use of protective equipment and proper storage conditions, are essential to prevent accidents.

Benzoyl Peroxide (BPO)

Applications:

Polymerization Initiator: Similar to TBPB, BPO is widely used as a free radical initiator in the polymerization of styrene, acrylics, and other monomers. It is particularly favored in the production of polystyrene and related copolymers.

Acne Treatment: BPO is a common active ingredient in over-the-counter acne medications. It works by reducing the number of bacteria on the skin and promoting the shedding of dead skin cells, which helps prevent clogged pores.

Bleaching Agent: It is used in the bleaching of flour, cheese, and other food products, enhancing their appearance and shelf life.

Safety and Handling:

BPO is known for its irritant properties, particularly to the skin and eyes. It can cause redness, peeling, and discomfort when applied topically. Additionally, BPO is a strong oxidizer and should be handled with care to avoid combustion risks.

Di-Tert-Butyl Peroxide (DTBP)

Applications:

Polymerization Initiator: DTBP is extensively used in the polymer industry as an initiator for the polymerization of ethylene, styrene, and other monomers. Its decomposition releases free radicals that initiate and sustain the polymerization process.

Cross-Linking Agent: In the production of polyethylene and other polymers, DTBP acts as a cross-linking agent, enhancing the mechanical properties and heat resistance of the final material.

Chemical Synthesis: DTBP is employed in various organic synthesis reactions where free radicals are required to initiate or propagate the reaction, making it a versatile reagent in chemical manufacturing.

Safety and Handling:

DTBP is a hazardous material that can cause skin and eye irritation. It is also a potent oxidizer and poses fire and explosion risks. Proper storage and handling procedures, including the use of explosion-proof equipment and adequate ventilation, are necessary to ensure safe use.

English

English 中文简体

中文简体